The industrial sector is the largest energy-consuming sector in Pakistan, accounting for over 40% of total final energy consumption. This presents a substantial opportunity to improve energy efficiency, reduce production costs, and enhance export competitiveness in international markets.

Pakistan’s industrial energy intensity stands at 0.117 kgoe per USD GDP (PPP), which is significantly higher than many regional economies. This indicates inefficiencies in industrial energy use and highlights the urgent need for targeted interventions.

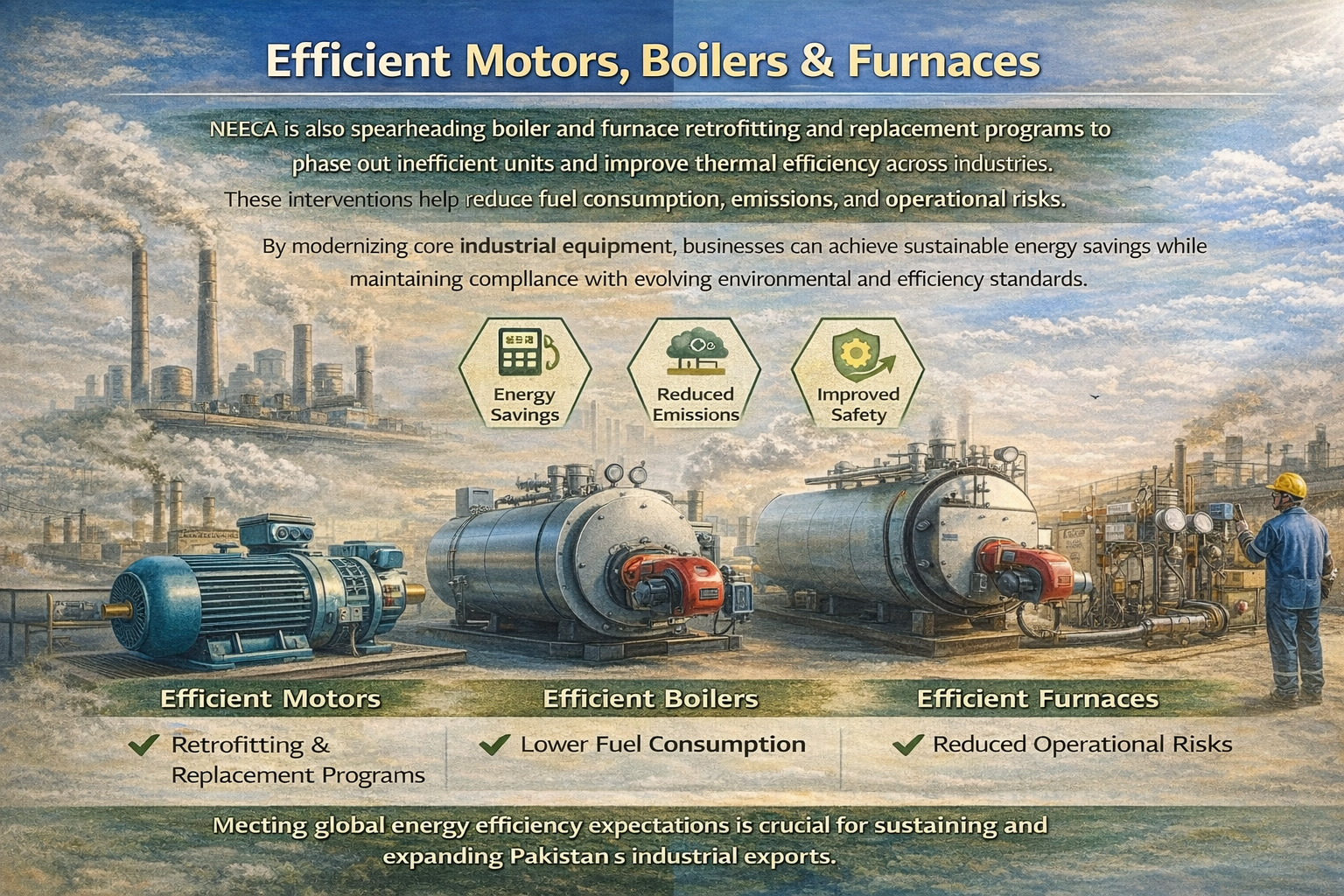

At the same time, international markets are increasingly demanding products with higher energy efficiency and lower carbon footprints. Meeting these expectations is essential for sustaining and expanding Pakistan’s industrial exports.

In line with its mandate, NEECA has launched a range of targeted interventions to improve energy efficiency, reduce emissions, and strengthen industrial competitiveness. A key initiative is the implementation of Minimum Energy Performance Standards (MEPS) for large industrial motors.

The adoption of high-efficiency motors leads to substantial electricity savings, reduced operational costs, peak load reduction, and lower CO2 emissions. These improvements directly enhance productivity across multiple industrial segments.

NEECA is also spearheading boiler and furnace retrofitting and replacement programs to phase out inefficient units and improve thermal efficiency across industries. These interventions help reduce fuel consumption, emissions, and operational risks.

By modernizing core industrial equipment, businesses can achieve sustainable energy savings while maintaining compliance with evolving environmental and efficiency standards.

NEECA emphasizes mandatory energy audits, the adoption of structured energy management systems, and the deployment of trained energy managers in designated industrial facilities. These measures enable industries to systematically identify inefficiencies and implement cost-effective energy-saving actions.

Effective energy management not only lowers energy costs but also strengthens resilience, improves operational control, and supports long-term sustainability goals.

NEECA’s interventions have the potential to deliver an estimated 39% total energy saving across the industrial sector. Key industries such as textiles, cement, steel, sugar, and leather can significantly improve energy performance while boosting productivity and export competitiveness.

Industrial stakeholders are encouraged to collaborate with NEECA and actively participate in energy efficiency programs. Implementing energy management systems, conducting regular energy audits, and upgrading to efficient motors, boilers, and furnaces can deliver immediate and long-term benefits.

Join NEECA in this transformative journey to unlock the immense energy-saving potential of Pakistan’s industries. Together, we can strengthen competitiveness, reduce emissions, and position Pakistan as a regional leader in energy-efficient industrial development.

Follow us on the following Links